High-quality die-cast aluminum and zinc

Highest quality and precision through the production of die-cast parts in the third generation, including special alloys and alloys with a high magnesium content.

From design to final treatment, just the way you want it.

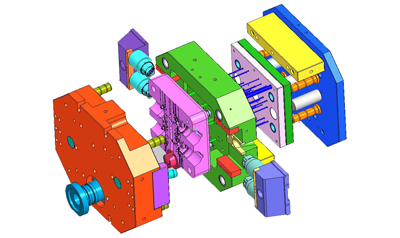

Design

All molds, tools, jigs and fixtures are manufactured in-house.

Demo Casters has an in-house design department that deals with all customer requirements.

This includes product part drawings, tool designs, 2D and 3D modeling,

assembly drawings, drafts and prototypes.

If required, reverse engineering, finite element methods and structural analyses are carried out.

Mold flow analyses and thermal scans of tools can be provided on request.

provided. Using the latest industry standard 2D and 3D software, we can optimize your product design through small changes or reduce production costs through weight reduction.

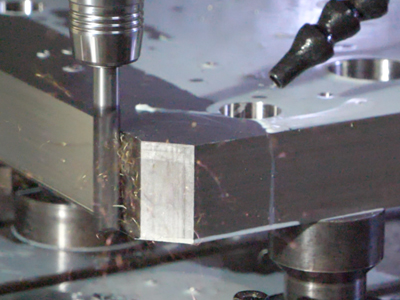

Mold making

Our team of outstanding toolmakers, machinists and fitters in our own workshops produce all the die-casting molds required for production.

To guarantee the highest quality standards

all holding and clamping devices as well as cutting tools for production are manufactured in-house.

Only the most modern and sophisticated machines are used in our toolmaking department. These include CNC turning centers, wire-cutting machines, spark erosion machines, surface grinding machines, cylindrical grinding machines and many other state-of-the-art precision machines from Makino, Haas, Mitsubishi, Agie Charmilles, Chmer, Roboform, Okomoto, Chevalier and Praga.

The exact size measurements required for precision mold making are carried out using optical coordinate measuring

coordinate measuring machines.

We manufacture precision tools from the best

materials using the most modern methods, thereby guaranteeing high quality and a long tool life.

Die casting machines

Demo Casters is equipped with die casting machines from 80t to 400t mold clamping force. The machine park includes machines with 80t, 120t, 150/180t and 350/400t. Through strategic partnerships, Democasters also has 600t and 800t machines at its disposal.

All machines come from the most renowned

manufacturers from Switzerland, Germany, Japan and Taiwan.

Our performance spectrum for die-cast parts ranges from 2.6g to 5.5kg.

All systems are PLC-controlled and equipped with many innovative functions. Damping valves

protect the tools from damage

damage caused by shocks and vibrations. TFI systems

(turbulence-free injection) or the Parashot process suppress any kind of turbulence, air inclusions or shaking of the molten metal during the injection phase.

of the molten metal in the injection phase

for a higher quality surface and better mechanical properties. The machines have the ability to store 300 to 500 different die presets for each product.

We also use fully automated robots that run through the entire process unmanned, from loading the furnaces with metal to auto-injection and mold casting to automatic extraction and delivery of the mold by conveyor belt.

Trimming

The castings are trimmed on conventional and hydraulic presses. For special

We have specially manufactured presses with ejection via bottom cylinders. Our

presses are equipped with safety devices such as two-hand control or light barriers. Compressed air blowers, which are triggered by foot switches, are available for cleaning chips and cuttings.

Machine processing

We carry out all types of prefabrication such as drilling, thread cutting, reaming, polishing,

diamond turning, thread chasing, taper drilling or groove cutting. The machining processes

with conventional, CNC or SPM machines as well as with high-precision lathes from Schaublin

lathes from Schaublin, Metzger or other renowned manufacturers.

Vibratory finishing

We use machines from Walther Trowal for high-quality vibratory finishing and drying, as well as the fully automatic system from Acton Finishing. Through the use of different

grades of deburring and polishing media made from ceramic, plastic or non-toxic composite materials, we produce top-quality surfaces. All systems are automated and have time control for precise processes.

Powder coating

Among other things, Demo Casters has a state-of-the-art powder coating system from Wagner with PLC-controlled spray guns. A specially tailored, fully automatic pre-treatment system

in conjunction with the 9-tank process produces one of the most robust powder-coated surfaces in the industry. A comprehensive testing facility is available in our laboratory to test and inspect the powder-coated parts in accordance with the ASTM standard.

Finishing

We offer a wide range of surface treatments

and coating options from zinc passivation, zinc plating, nickel chrome plating, nickel satinizing, CMD/KTL coating, anodizing

and painting to any other type of surface treatment requested by the customer.

Assembly and testing

We also undertake special installations for our customers. Special tests such as mechanical

load tests or roughness measurements

of the surfaces can also be carried out by us.

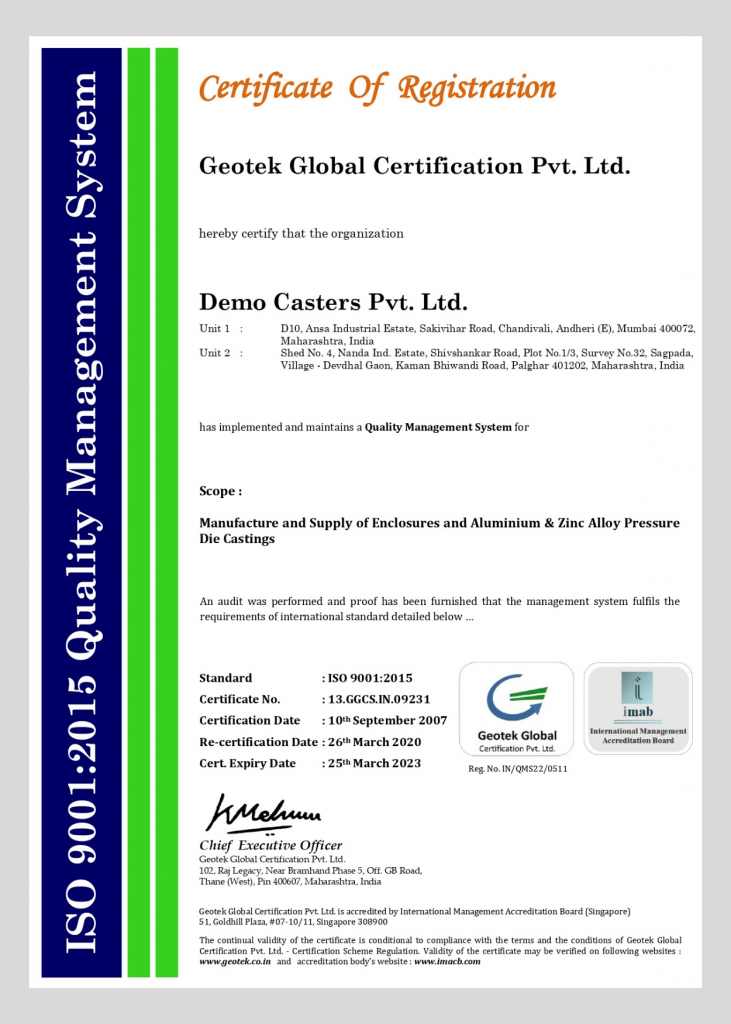

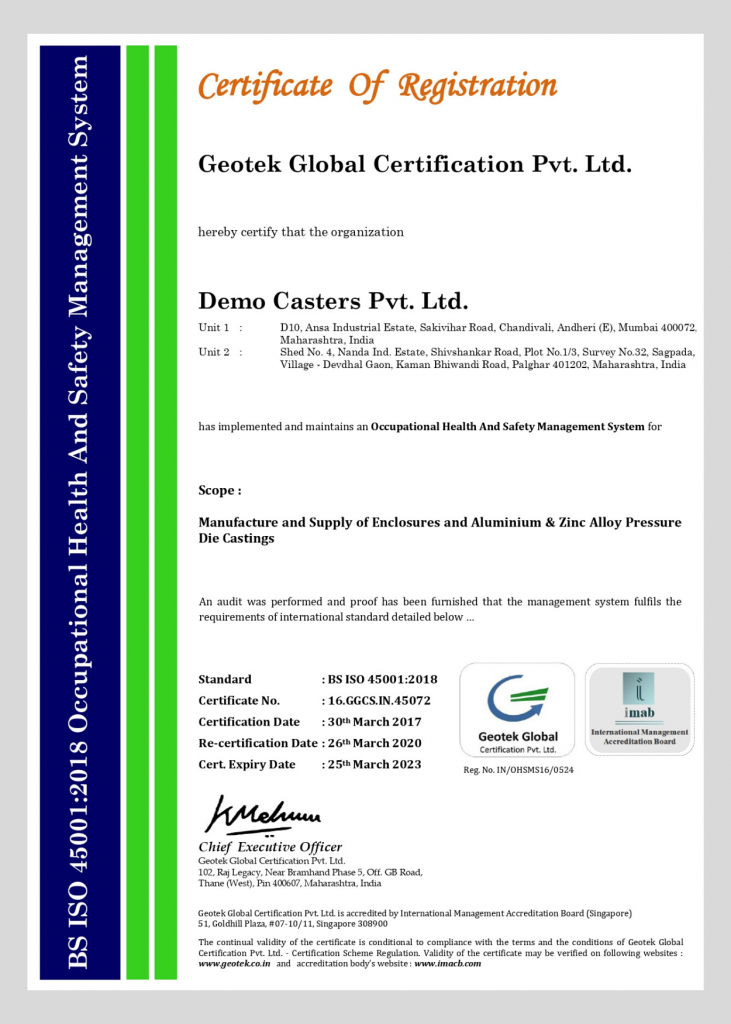

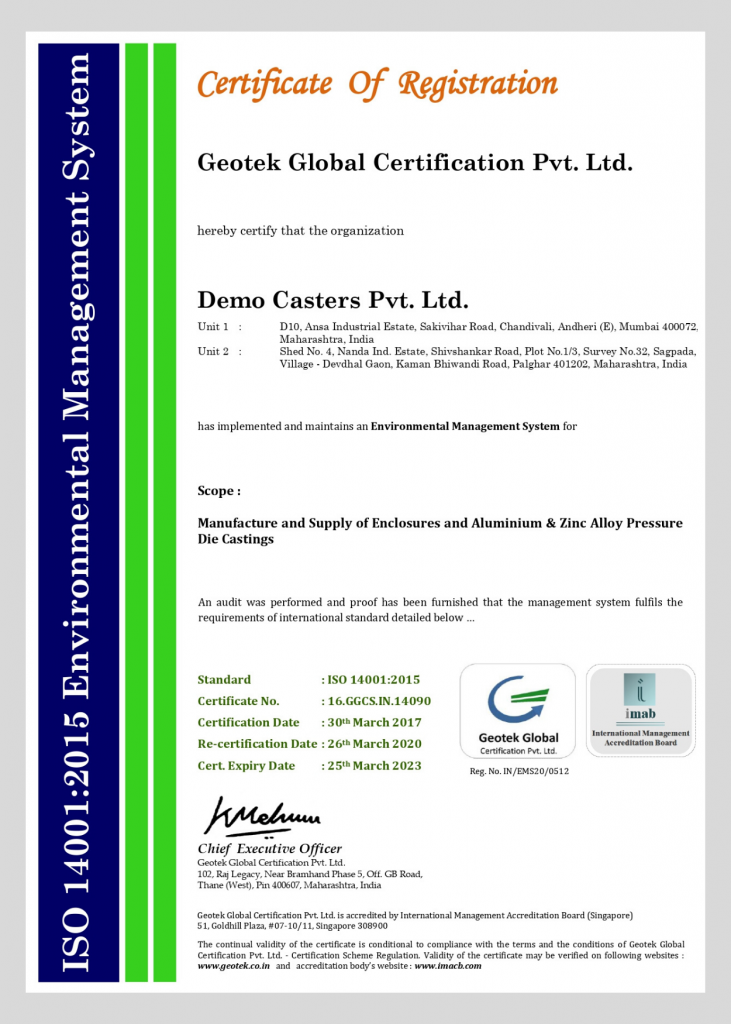

Certificates

|

|

|